by tejastubular | May 15, 2023

We rigorously examine every weld seam to identify any defects and apply magnetic particle inspections on pipe ends to pinpoint any steel or processing-related concerns.

by tejastubular | May 15, 2023

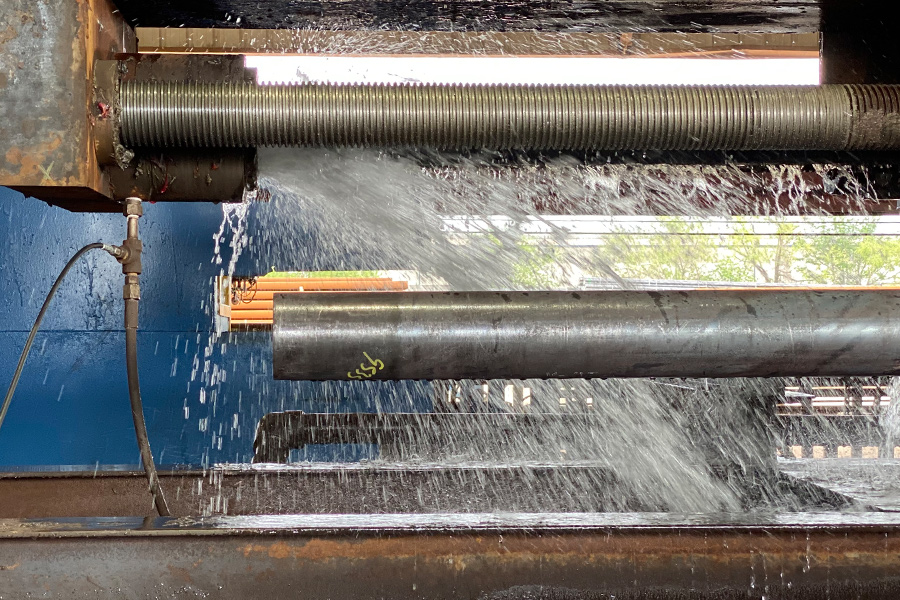

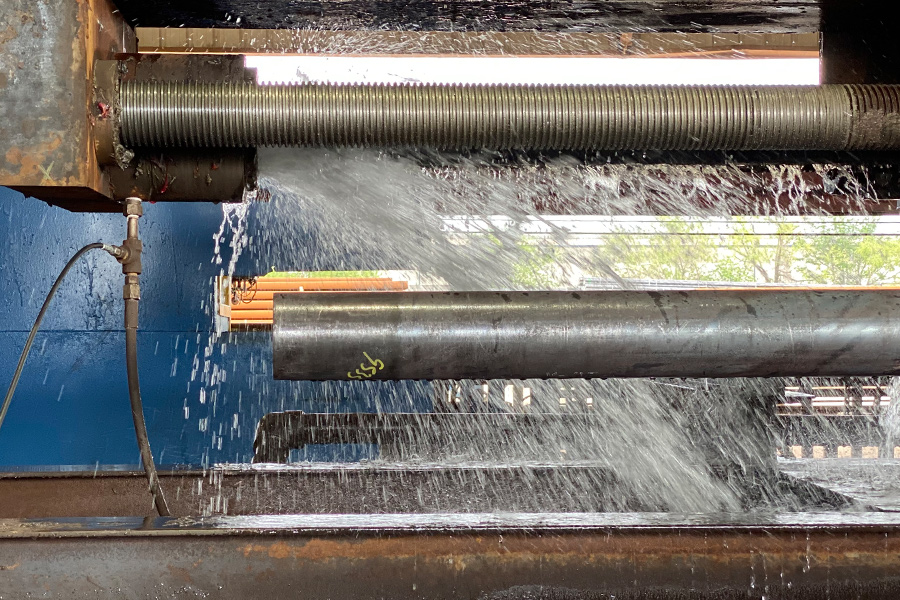

Our hydro-testing equipment is state-of-the-art and can test up to 20,000 psi. It’s also adjustable in terms of length and pressure, making it highly versatile.

by tejastubular | May 15, 2023

We use advanced technology CNC machines and automated machining for precision threading on our end-finishing production lines. Our tubes exceed API standards and are fitted with Tejas Tubular couplings.

by tejastubular | May 15, 2023

After our manufacturing process, the pup joints are sent to our state-of-the-art painting area. Depending on their grade, each pup joint is given a distinct color coating.

by tejastubular | May 15, 2023

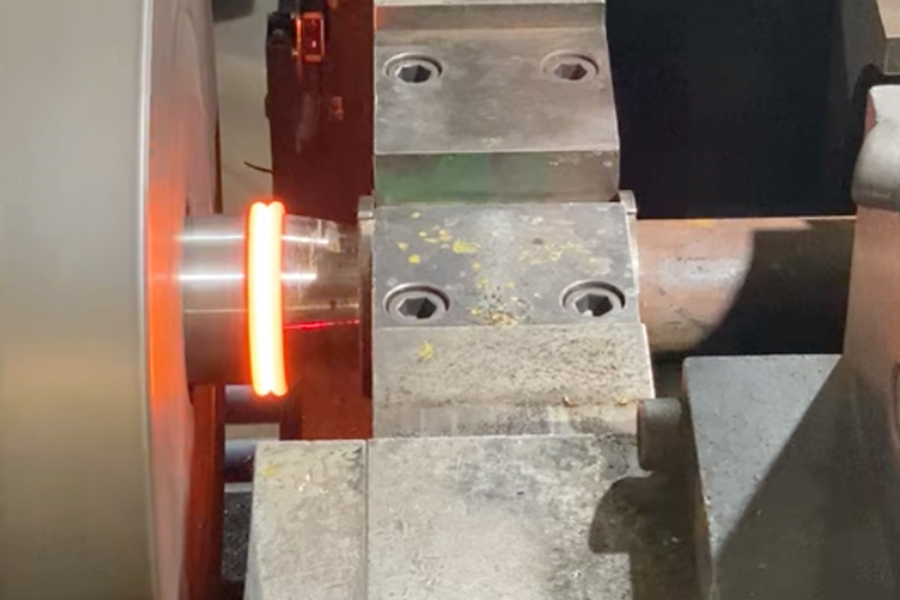

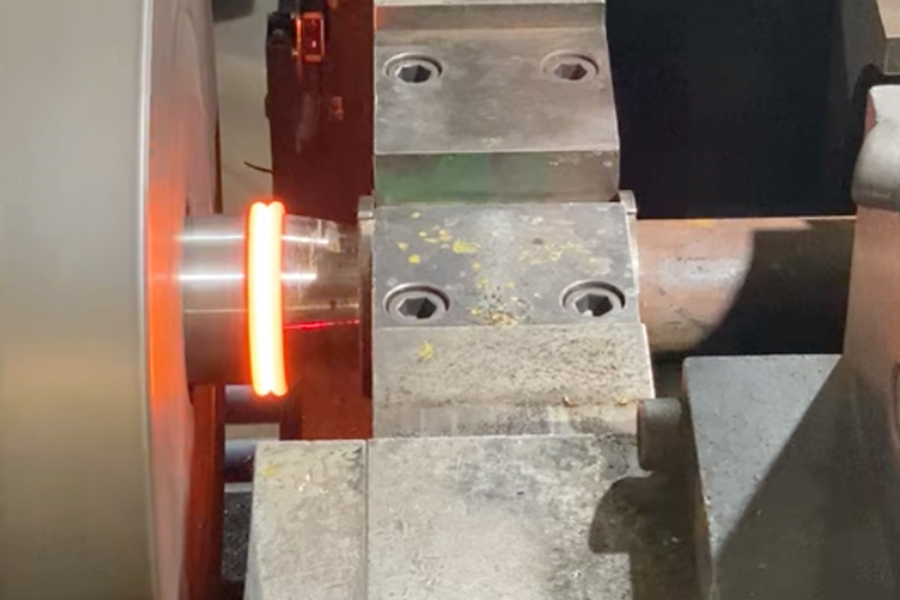

Our company utilizes in-house inertia welding machines to fuse machined tool joints to tube ends through friction heat. This process is used to create various products, including our line of new and reconditioned workover string joints.