by tejastubular | May 15, 2023

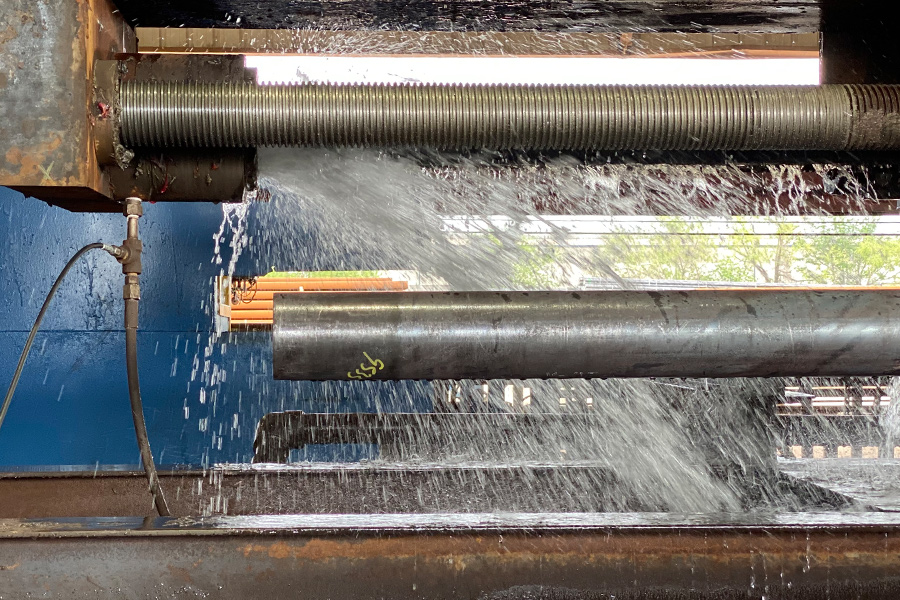

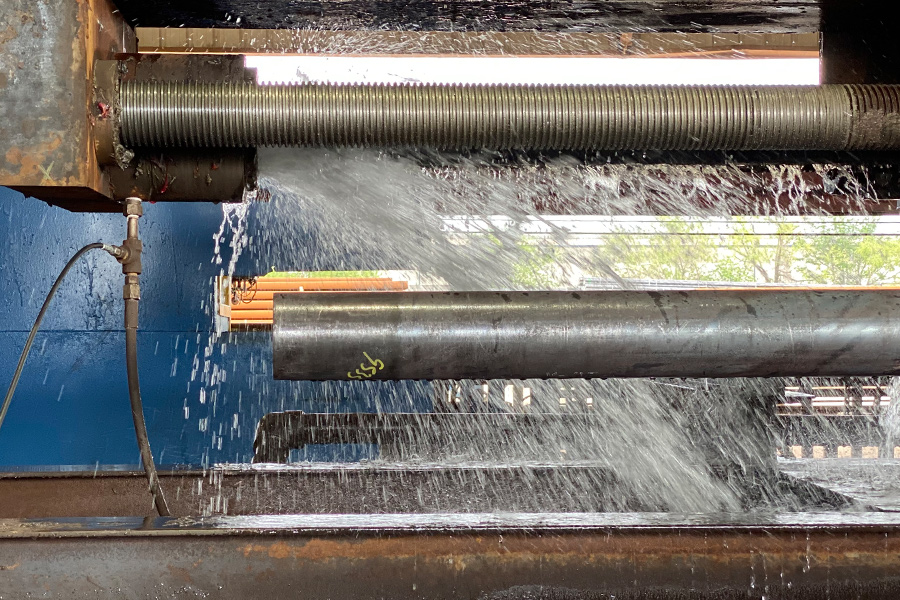

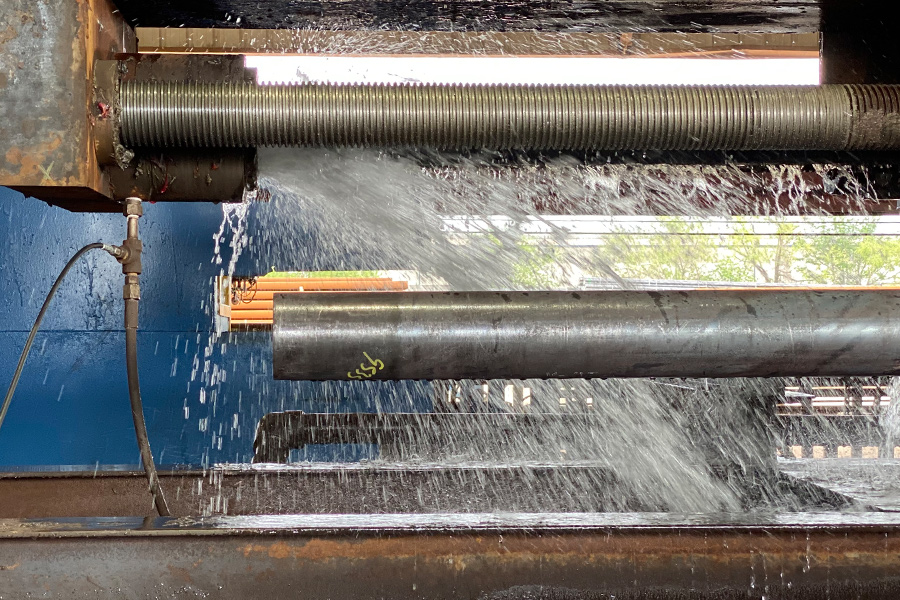

Our hydro-testing equipment is state-of-the-art and can test up to 20,000 psi. It’s also adjustable in terms of length and pressure, making it highly versatile.

by tejastubular | May 16, 2023

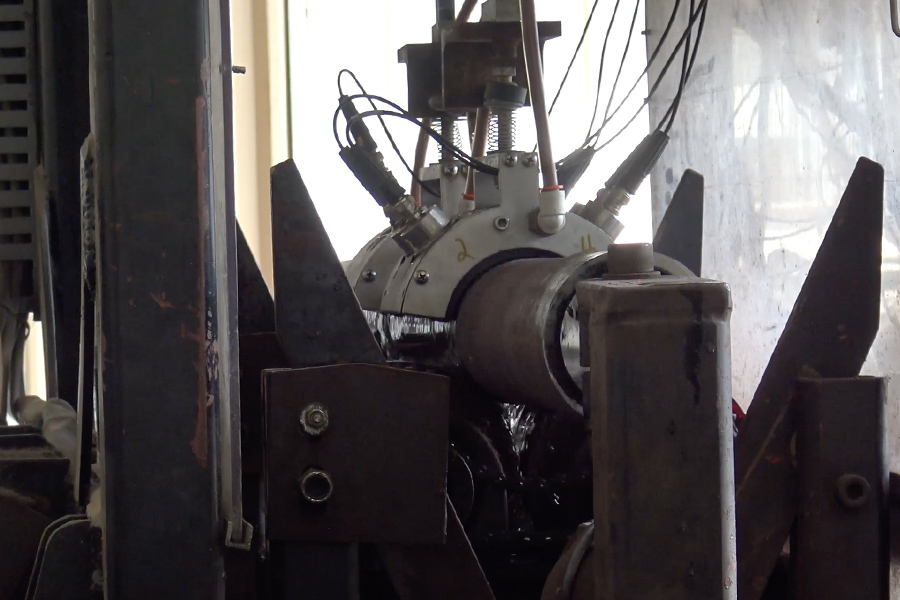

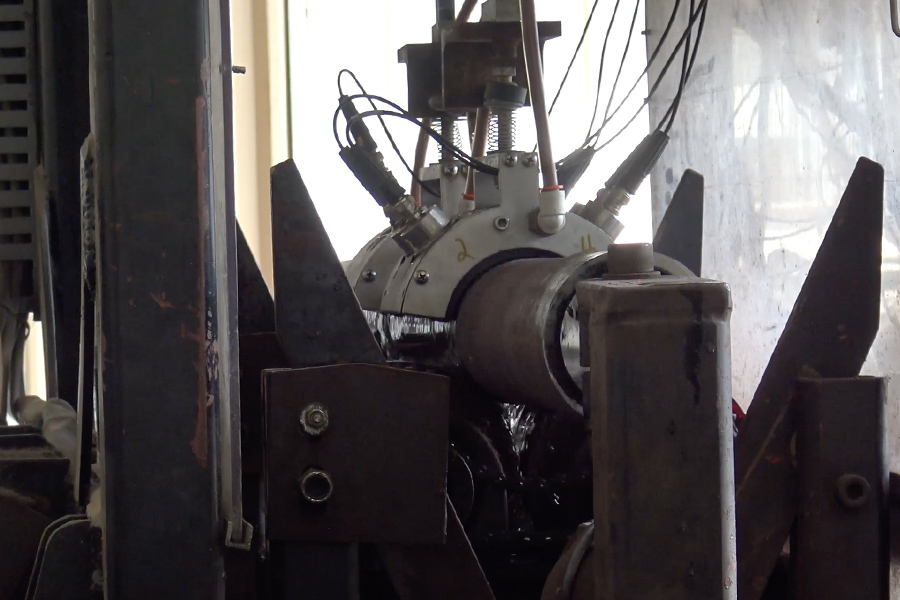

Tejas Tubular is the first in te industry to build and use a Full Body Ultrasonic Inspection for it’s Pup Joints. This inspection better detects cracks, pits, and other imperfections on the ID of the pup joint.

by tejastubular | May 15, 2023

We use advanced technology CNC machines and automated machining for precision threading on our end-finishing production lines. Our tubes exceed API standards and are fitted with Tejas Tubular couplings.

by tejastubular | May 15, 2023

After our manufacturing process, the pup joints are sent to our state-of-the-art painting area. Depending on their grade, each pup joint is given a distinct color coating.

by tejastubular | May 15, 2023

Our CNC machines can produce high-quality threads. By bullet-nosing, we ensure the easy use of internal plastic coating on EUE pup joints.