by tejastubular | May 15, 2023

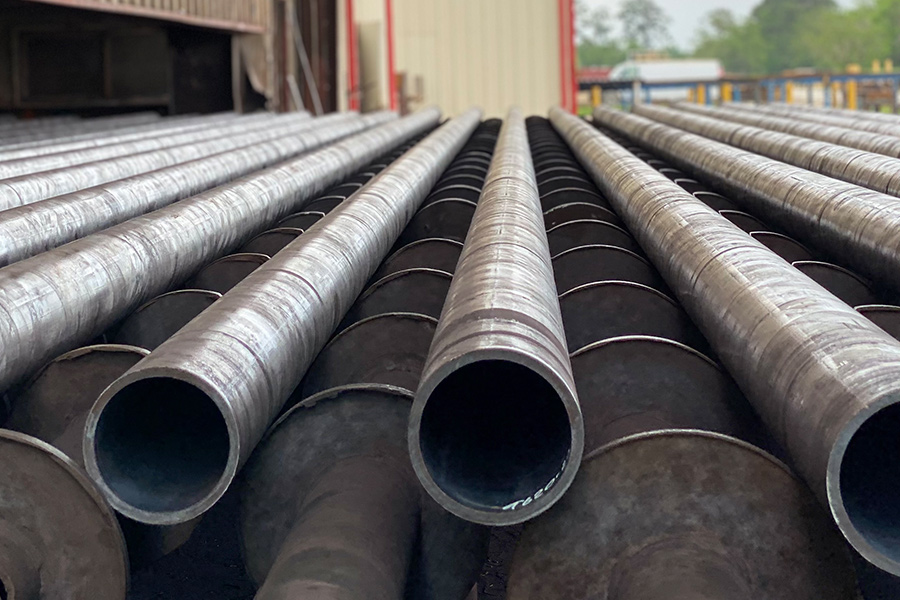

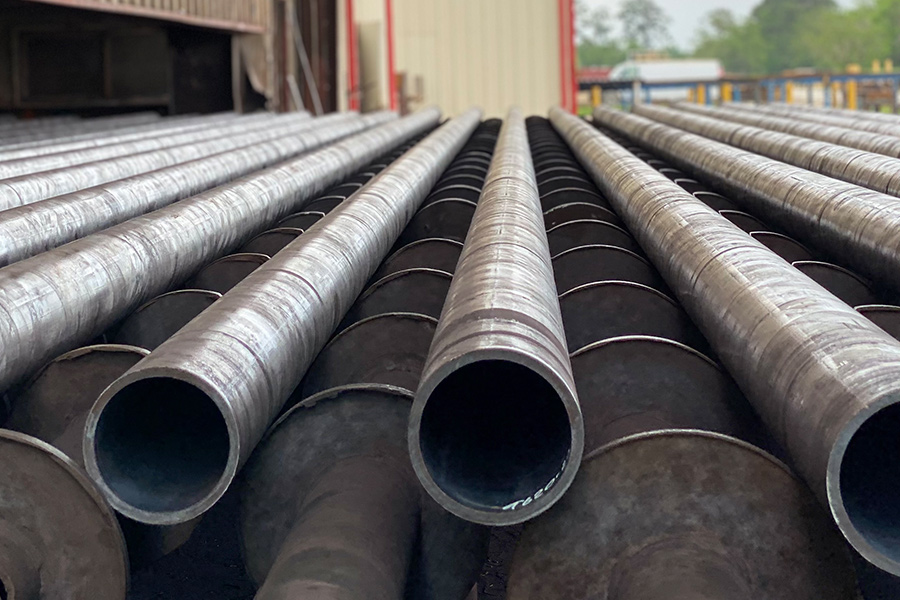

Our tubing source is carefully selected from top mills to ensure exceptional quality with great attention to detail.

by tejastubular | May 15, 2023

We have multiple heat-treating lines to ensure quick turnarounds. Our manufacturing process includes two types of heat treatment: quench and temper (Q&T), and normalizing (norm). Our team uses induction furnaces for the heat treatment of products.

by tejastubular | May 15, 2023

We start with a specialized chemistry carbon alloy tube body. Our 4130 Carbon alloy, green tube starts its journey by transiting a slot furnace to be heated to 2,300 degrees. Once at the required temperature, the end is secured in a set of precision machined dies. The...

by tejastubular | May 15, 2023

The furnace exerts a tremendous amount of energy on the green tube, and the unfortunate result is pipe that is not perfectly straight. Thus, after coming out of the temper furnace, the pipe enters a crossroll and gag straightener where it is put back into alignment....

by tejastubular | May 15, 2023

Our ASNT-certified crew conducts Non-Destructive Testing on pipes ranging from 2 3/8” to 9 5/8”. We employ a special tube-End Area Inspection and a Full-Body Electro-Magnetic Inspection that consists of four simultaneous scans, including longitudinal, transverse, wall...