The furnace exerts a tremendous amount of energy on the green tube, and the unfortunate result is pipe that is not perfectly straight. Thus, after coming out of the temper furnace, the pipe enters a crossroll and gag straightener where it is put back into alignment. Once the pipe is straightened and passes QC inspection, it is sent to the next part of the process or into storage for upcoming orders.

Straightening

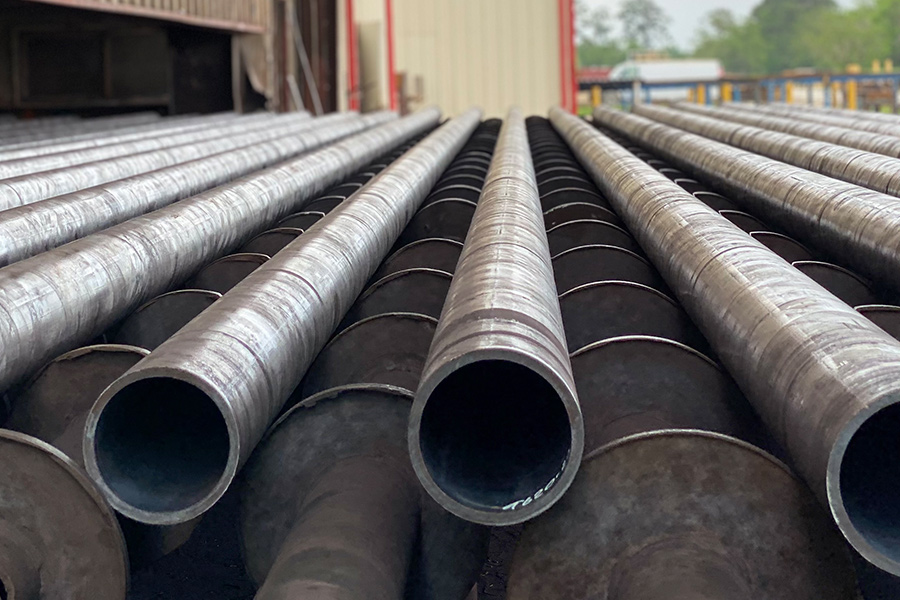

Casing, Drill Pipe, Pup Joints, TTS6 Black, TTS6/8, Tubing